As we all know that, some of the farms, there are AC electricity pumps which has been used, drived by AC grid power or disel

generator before.Once the power source are replaced by solar, Clients always want to know How much solar panels shall be

used and which power of solar pump inverter is matching with it and which kind of main devices are needed? We have explaine

in my previous article to explain that the solar panels we will use that is around 1.3-1.5 times more than power of AC pump.

We need to use 105pcs 550W mono solar panels, 15pcs in series and 7 in parallel. Total solar power 57.75kw.

1. Photovoltaic Array

1.1 Specification of mono Crystalline PV module

Mechanical Specifications | |

Cell Type | Mono Crystalline |

Number of cell | 144 / monocrystalline silicon |

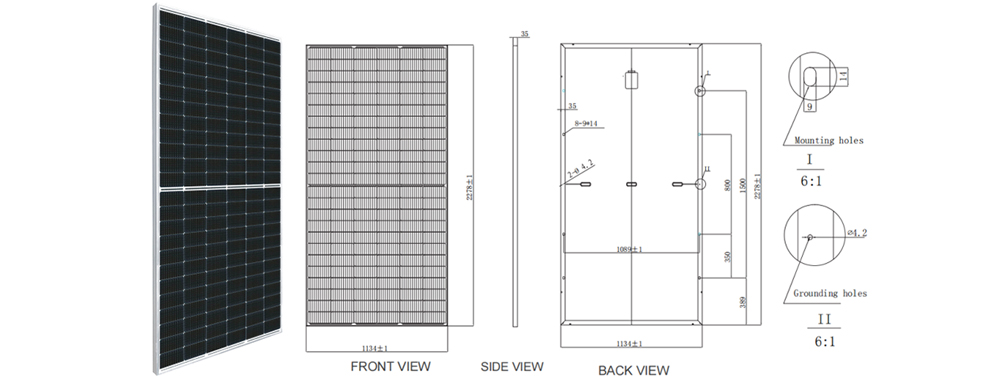

Dimension | 2278mm / 1134mm / 35mm |

Weights | 29kg |

Front Glass | 3.2mm tempered low iron glass |

Frame | Clear anodized aluminum alloy |

Junction Box | IP68 with bypass diodes |

Connector | MC4,QC4 |

Output cables | 4.0mm²,+300mm,-300mm Customized Length |

1.2 Mechanical Drawing

1.3 PV module Parameters

Electrical Characteristics at Standard Test Condition (STC) | |

PV Module Type | Mono Crystalline |

Max. Power at STC (Pmax) | 550 W |

Short Circuit Current(Isc) | 13.82A |

Open Circuit Voltage(Voc) | 50.2V |

Max. Power Current (Impp) | 12.98A |

Max. Power Voltage(Vmpp) | 42.4V |

Module Efficiency | 21.29% |

Power Tolerence | 0 ~ + 5W |

STC: 1000W/m2 irridiance, 25℃ cell temperature, AM=1.5 | |

Temperature Characteristics | |

Nominal Operating Cell Temperature (NOCT) | 45℃±2℃ |

Temperature Coefficient of Pmax | -0.35% ℃ |

Temperature Coefficient of Voc | -0.27% ℃ |

Temperature Coefficient of Isc | 0.05% ℃ |

System Intergration Parameters | |

Max. System Voltage | VDC 1500V |

Max. Series Fuse | 25A |

Working Temperature | -40 ~ +85℃ |

1.2 Frame, Junction box and terminals

The material of frame is clear anodized aluminum alloy with weatherproof. Junction box is IP67.

1.3 Appearance of module

All PV module surfaces is cleaned to ensure that the appearance meets the following requirements

1) , Frame clean, smooth, no burr, no corrosion spots.

2),There are no cracking, no bending, no damage on PV module surface.

3),There are no scratches, no wrinkles, no obvious convex or concave on the backside of PV module

4),Junction box is glued well and firmly.

5), PV module wiring connection is sealed, The polarity is marked accurately and obviously.

1.4 PV module nameplate

Each PV module must have identification with the following information:

1), Name of the manufacturer

2), Model or Type Number, Serial Number

3),Main parameters of PV module

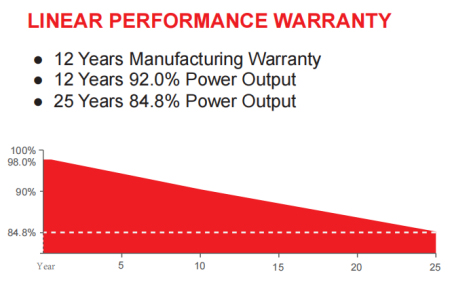

1.5 Industry leading warranty based on nominal power

25-year Linear power warranty, 12-years product warranty

1.6 Qualification and Certification

The supplier of PV module have the certification of ISO9001, ISO14001,The pv module have pass the test of TUV, CE etc.

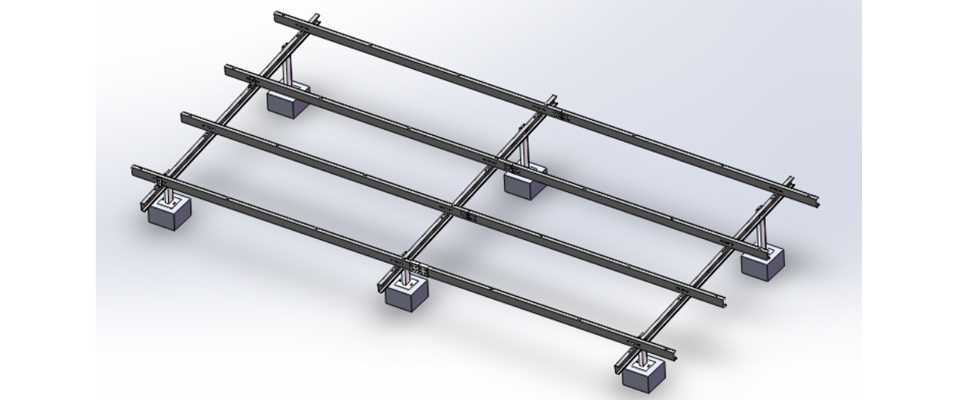

2. Mounting Structure for Ground-mounted PV array

2.1 Mounting Structure features

1) The modules support structure is mild steel, hot dipped galvanized for holding the PV modules.

2) Each panel frame structure is fabricated to be grouted on ground on its legs on cement base. It is of adequate strength

and appropriate design, which can withstand load of modules and high wind velocities up to 100 km per hour.

3) All nuts and bolts are made of very good quality and are corrosion resistant.

4) The structure is easy replacement of any module.

5) The array structure occupy minimum space without sacrificing the output from the PV panels.

Structure drawing for Ground-mounted structures will be supplied after the inspection of site.

3. solar pump inverter

Since AC pump is 50HP,equal to 37kw, so we keep solar pump inverter is same power as AC pump, then 37kw solar pump inverter is used.

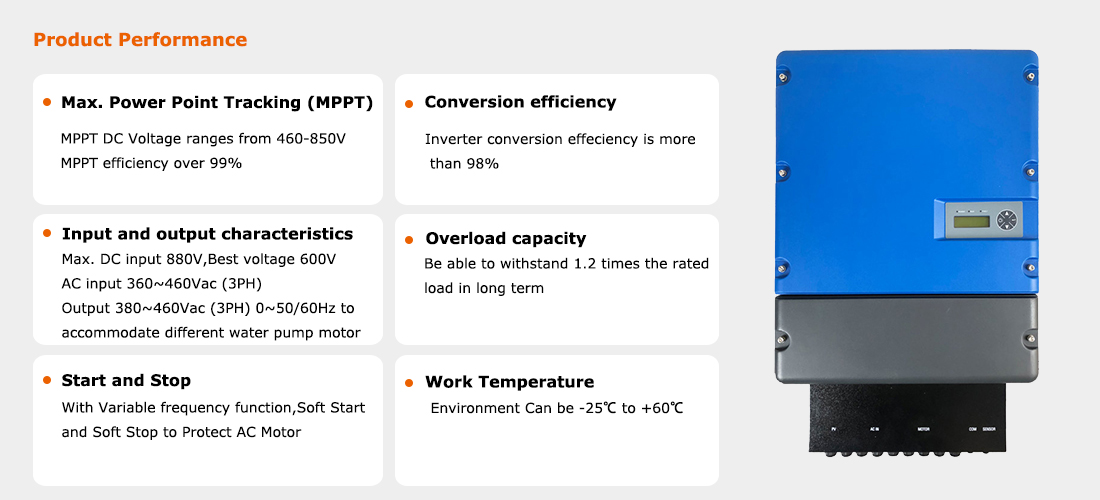

3.1 Features

-Drive power-matched any three-phase AC pump with 380V 50Hz

-Adopt advanced IGBT power module

- High conversion efficiency, low temperature rise, low noise, long lifespan

-Advanced MPPT technology, efficiency >99%

- Fully automatic operation, it can store operation date for 10 years

-Perfect system protection, high reliability

- LCD display

-Communication:GPRS is optional

-Modular design, easy to install, operate, maintain

3.2 parameters of 37kw solar pump inverter

Model | JNP37KH-V5 |

Max. Input DC voltage | 880Vdc |

Recommended MPPT voltage | 460-850Vdc |

Max. Input DC current | 100A |

Max. MPTT efficiency | 99% |

Number of Strings | 1 |

AC input voltage | 360-460Vac (1Phase) |

Input Frequency | 50/60Hz(±3%) |

Max. applicable motor output power | 45KW |

Rated output voltage | 380-460Vac 3 phase |

Output frequency range | 0-50/60Hz |

Rated output current | 86A |

Dimension(W/H/D) | 460x715x260 mm |

weight | 48kg |

Protective class | I |

Protection degree | IP65 |

Environment temperature | -25℃-+60℃ above 60℃ need derate operation |

Cooling method | Force cooling |

Display | LCD |

Altitude | 3000m; above 3000m need derate operating |

Noise emission | <50dB |

3.3 Solar pump inverter nameplate

Following details will be displayed on nameplate

1), Name of Manufacturer

2), Model Number

3), Serial Number

4), main parameters of inverter

3.4 Water level sensor

JN Solar Pump Inverter can protect pump from dry running and overflow through following methods.

1) Self-achieved: When the outlet of pump is out of the water resource, the system will stop work, and can restart automatically after

some time (can be adjusted, the factory default is 30 minutes ).

2) Detection measuring: Need to configure two pcs of water lever sensor, low level sensor (install at above 0.1m of water pump inlet)

& high level sensor(above 1~3m of low level sensor). The system will stop when low level sensor is out of water surface, and the

system will restart when water level is higher than high level sensor.

3) Tank full Protection

Can achieve this function through two pcs of water lever sensor, low level sensor (install at below 1~3m of high water level) &

high level sensor(install at the highest water level inside the storage tank). The system start work auto. when water level is

lower than low level sensor, and will stop immediately when water level reach up to high level sensor. And the system will

restart auto. when water level is lower than low level sensor.

3.5 Full Protection Function

Post time:2025-04-23